Tubular Barrier & Stanchion Systems

Specifically manufactured to suit Australian standards and conditions, Barrier and Handrail Systems are equally at home in industrial, commercial, municipal or general applications. National Pipeline Supplies stock the Webforge Monowills range and can help with all aspects of your project.

Due to its unique design, the Webforge Monowills system can be transported and erected quickly and economically in all applications. Provide us with the layout drawings for your project, and we can help with all the rest.

- Provide detailed layouts

- Manufacture to your requirements

- Manage quality control and documentation, and

- Fabricate the system to suit

We will source the complete access system for your requirements, including grating, if required. www.webforge.com.au/access

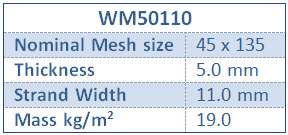

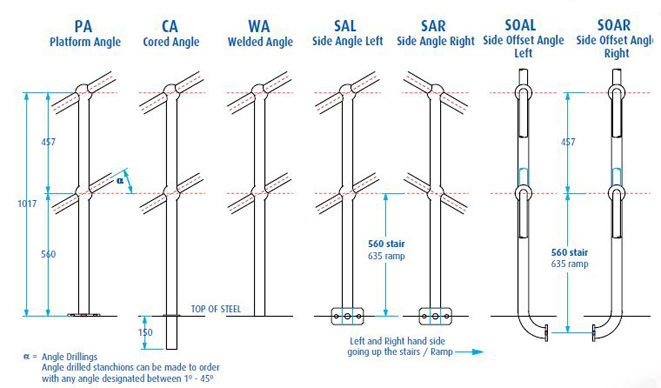

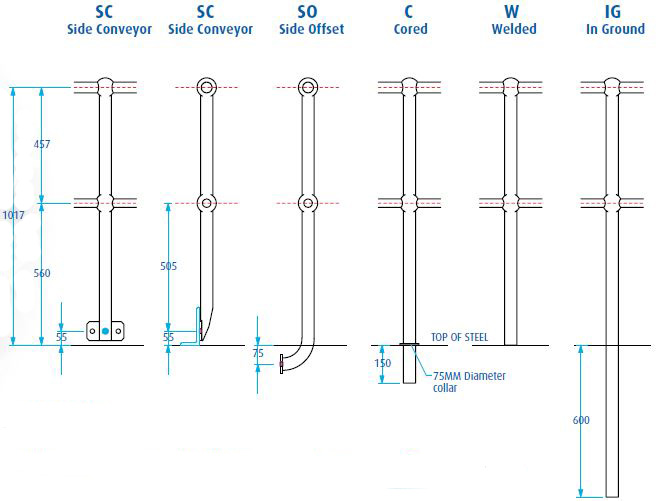

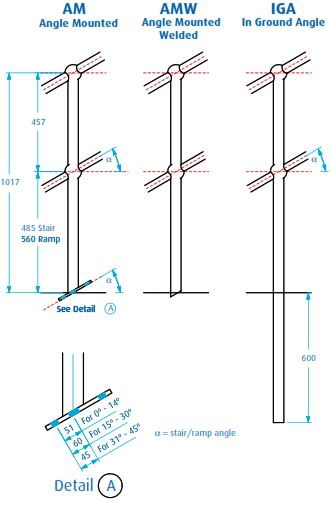

Standard Handrail Stanchions

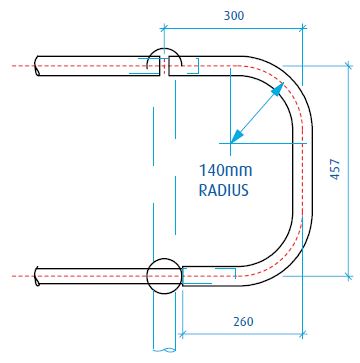

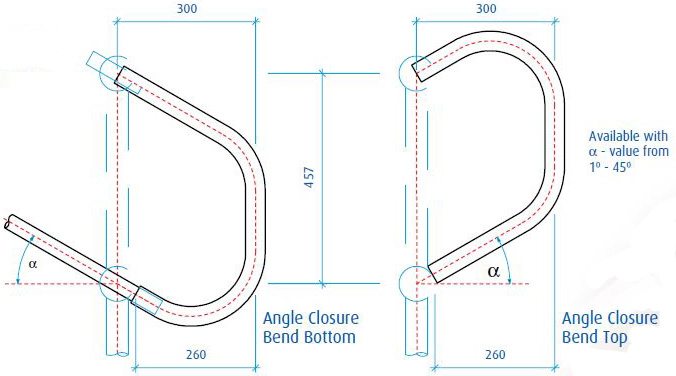

Horizontal and Angle Closure Bends

Your project can be supplied complete with stanchions, rails, bends, gates, kick plates, grating and stair treads. This system can be used in a multitude of applications including stairways, bridges, parking stations, schools, commercial premises, fire escapes, gangways, power stations, sewage treatment works and marinas. They also meet the requirements of government department codes.

Stairways - providing a steady tread under foot

Webforge stair treads are a common sight in numerous industries, including mineral processing, industrial, commercial and oil and gas. We can supply a system to suit any application that requires incline access to safe walkways, coupled with protective handrail systems, either fully welded or modular. Stair treads are available with a range of anti-slip nosings; including standard yellow reflective nosing, Webplate and perforated plate, providing the contrast and slip resistance required by AS/NZS 1657.

Available in a wide variety of base materials to fulfill your requirements and the site's environmental conditions, including Steel, Aluminium and FRP (Fibre-Reinforced Plastic) Grating; stair treads can be supplied with weld-in or bolt-in end plates.

Complemented by the handrail system, National Pipeline Supplies is able to provide full tread systems for any industry or application, and we can advise on the most appropriate base material and grating profile for your application. Provide us with your outline drawings, tread type, size and finish, and we will sort the rest. www.webforge.com.au/access/steel-grating/stair-treads

Serated Bars

Plain Bars

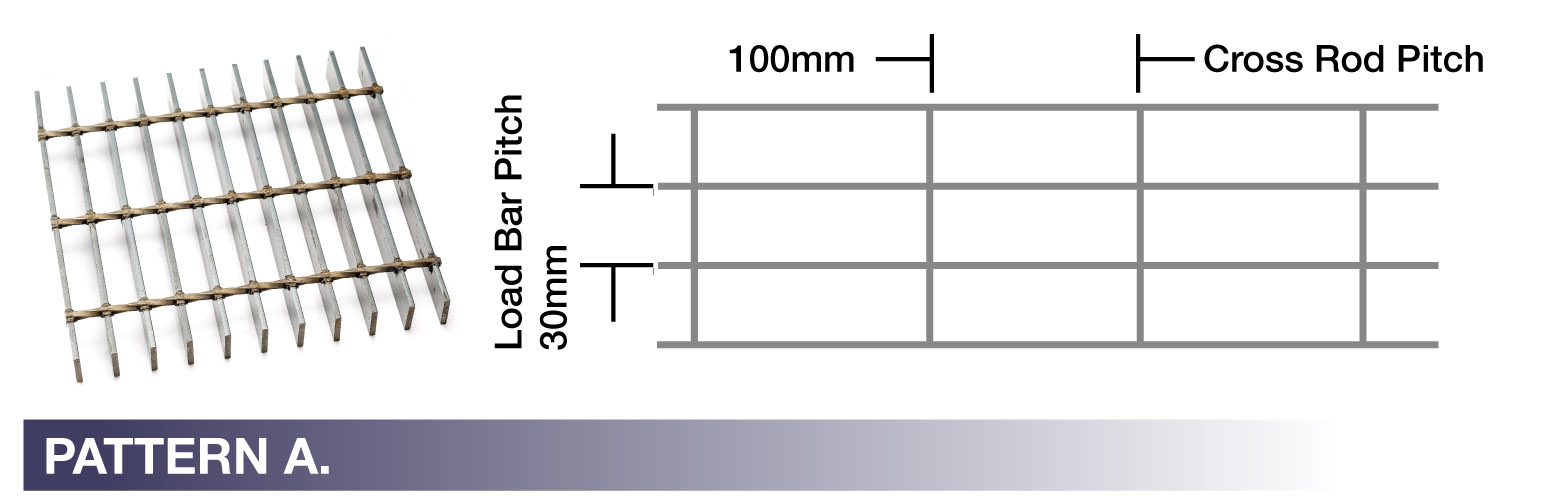

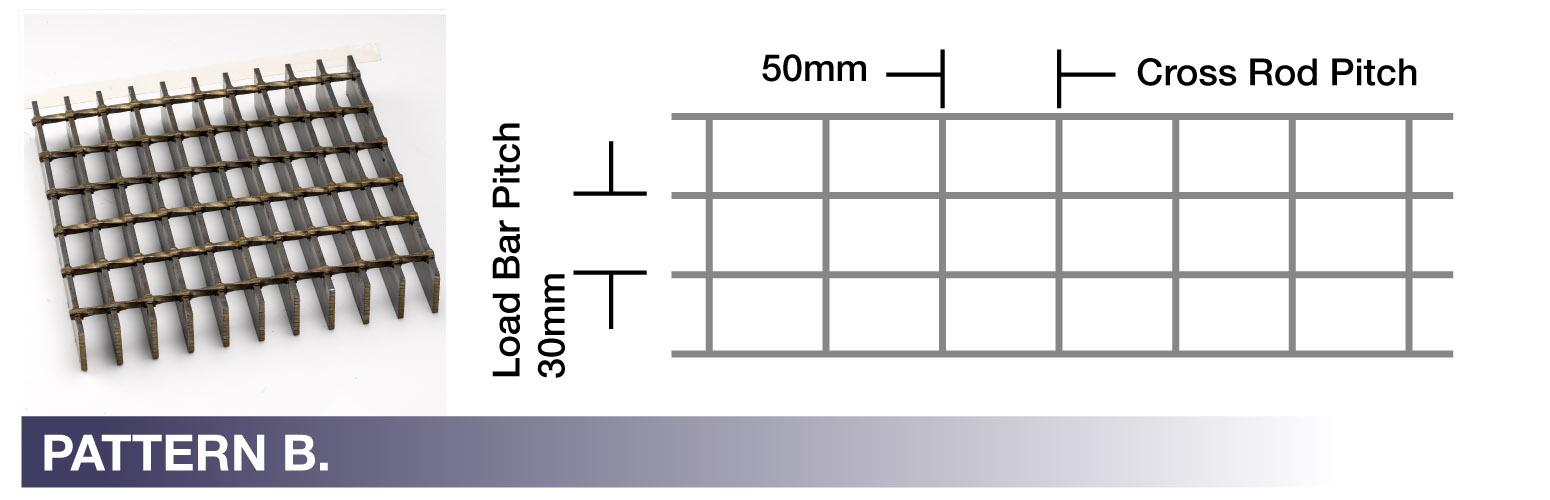

Grating

A & B patterns conform to the AS 1657 Code for Fixed Platforms, Walkways, Stairway and Ladders. www.webforge.com.au/access/steel-grating

These patterns are the most commonly specified and installed. This type of grating with its 30mm load bar centres has the greatest resistance to surface impact. It is used extensively in Power Stations, Refineries, Sewerage Treatment Plants, Grain Silos, Chemical Plants and for trafficable drain grates and stair treads. In serrated form, patterns A & B are used in wet, greasy areas especially in the oil industry on offshore production platforms.

NB: Serrations are not as effective in the B pattern because of the pitch of the cross rods.

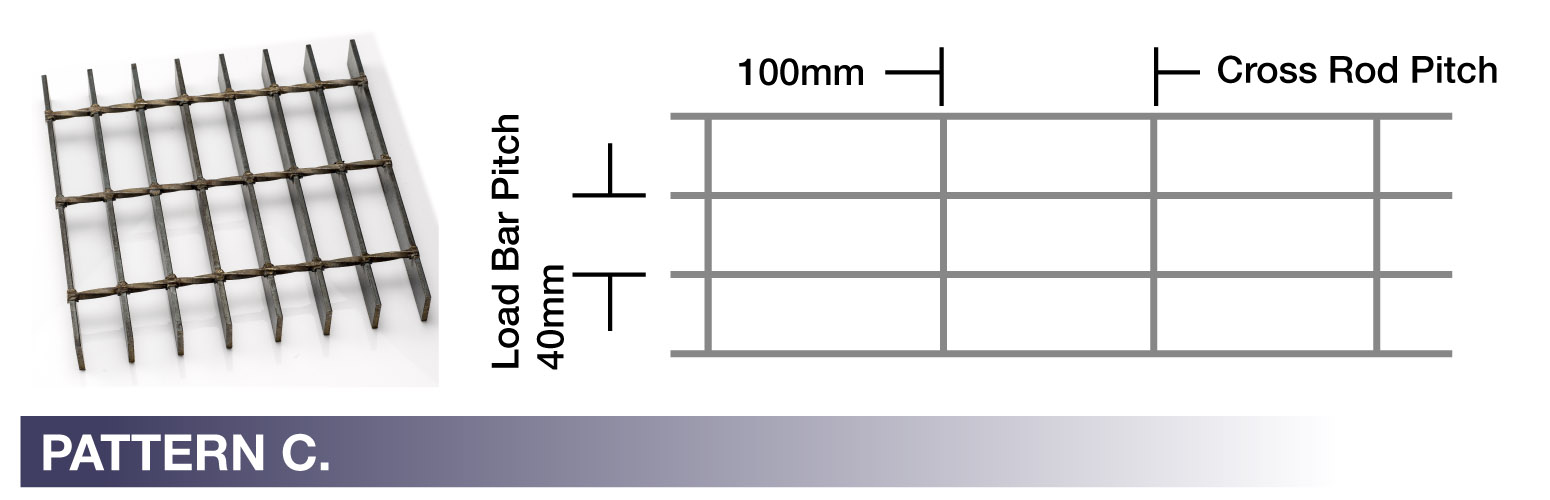

Patterns C

C patterns are lighter and more economical than the A & B Pattern, while still conforming to the requirements of AS 1657. This range is ideal in areas which do not have to withstand high impacts or heavy loading.

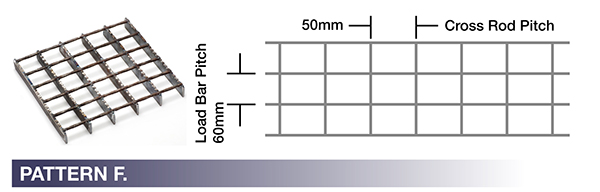

Pattern F

F pattern grating has been specifically developed for the mining industry where spillage of material onto floors is a problem. The large square openings (nominally 60 x 50) allow most materials to fall through the grating, thus keeping the walking surface clear and safe. This product is frequently specified for conveyor walkways and floors in crusher buildings, process plants and transfer stations.

NB: Serrations are not as effective in the F pattern because of the pitch of the cross rods.

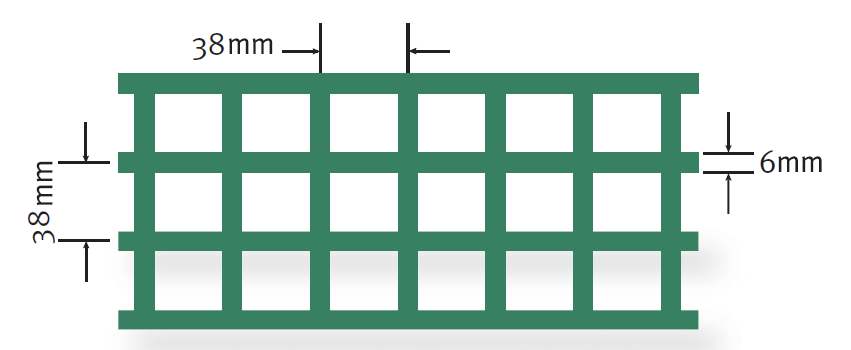

Fibre Reinforced Plastic Grating (FRP)

Fibre Reinforced Plastic (FRP) grating is a moulded, one-piece fiberglass reinforced plastic grating, available in standard panels or fabricated into customised panels ready for installation. www.webforge.com.au/access/frp-grating

The square pattern design and one-piece construction allows load to be transferred to the adjoining bars providing a superior load-carrying capacity. The load transfer assists in load distribution on the grating as well as on the support structure.

Smooth resin-rich vertical surfaces and tapered bars allow all debris to fall through the 70% open area panels.

The high resin-to-glass ratio provides maximum corrosion resistance to a wide range of chemicals frequently encountered in many industries. Continuous glass-fibre strands in alternating layers thoroughly whetted with the appropriate resin provides excellent corrosion resistance.

FRP comes in one standard panel size: 1200 x 3660mm; however custom sizes can be sourced for specific project requirements.

Slip Resistance

When selecting a product for flooring and walkway applications, slip resistance is an essential consideration. FRP Grating is supplied with an anti-skid surface as standard; the coarse grit embedded into the resin provides good slip resistance. Depending on application requirements, a plain top surface is also available.

FRP Grating Patterns available

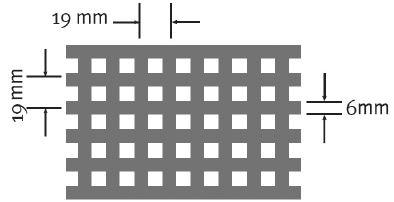

FRP grating is predominantly supplied in standard 38 x 38mm profile. However, we also offer FRP grating in a Mini Mesh profile, for applications with concerns of small objects falling through, or a requirement for reduced open area.

Available in all 3 resin types: Isopthalic Polyester, Vinyl Ester and Phenolic.

* Only available in 38mm deep bars

* Aperture is 12 x 12mm

Available in 2 resin types only: Isopthalic Polyester and Vinyl Ester.

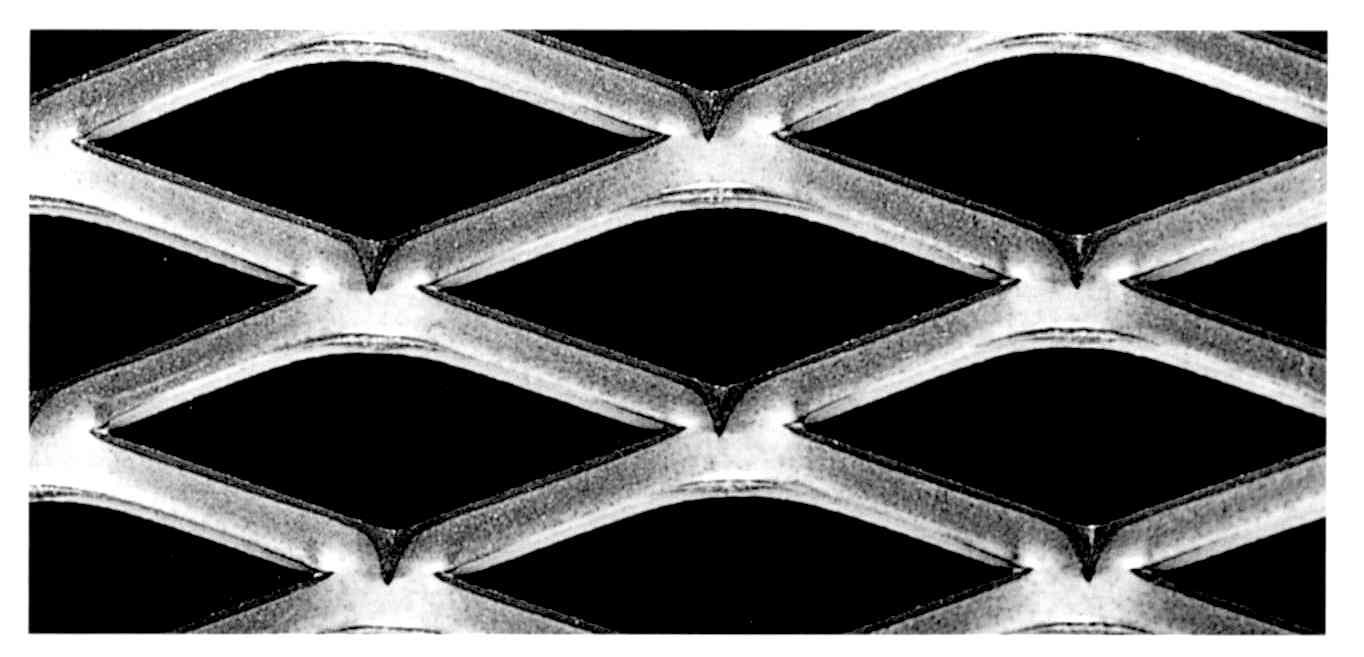

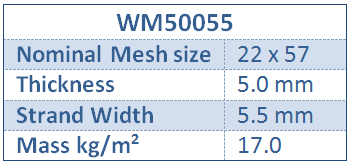

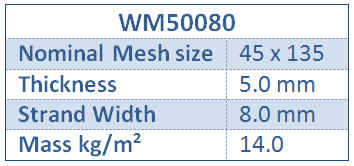

Gridwalk Walkway Patterns and Profiles

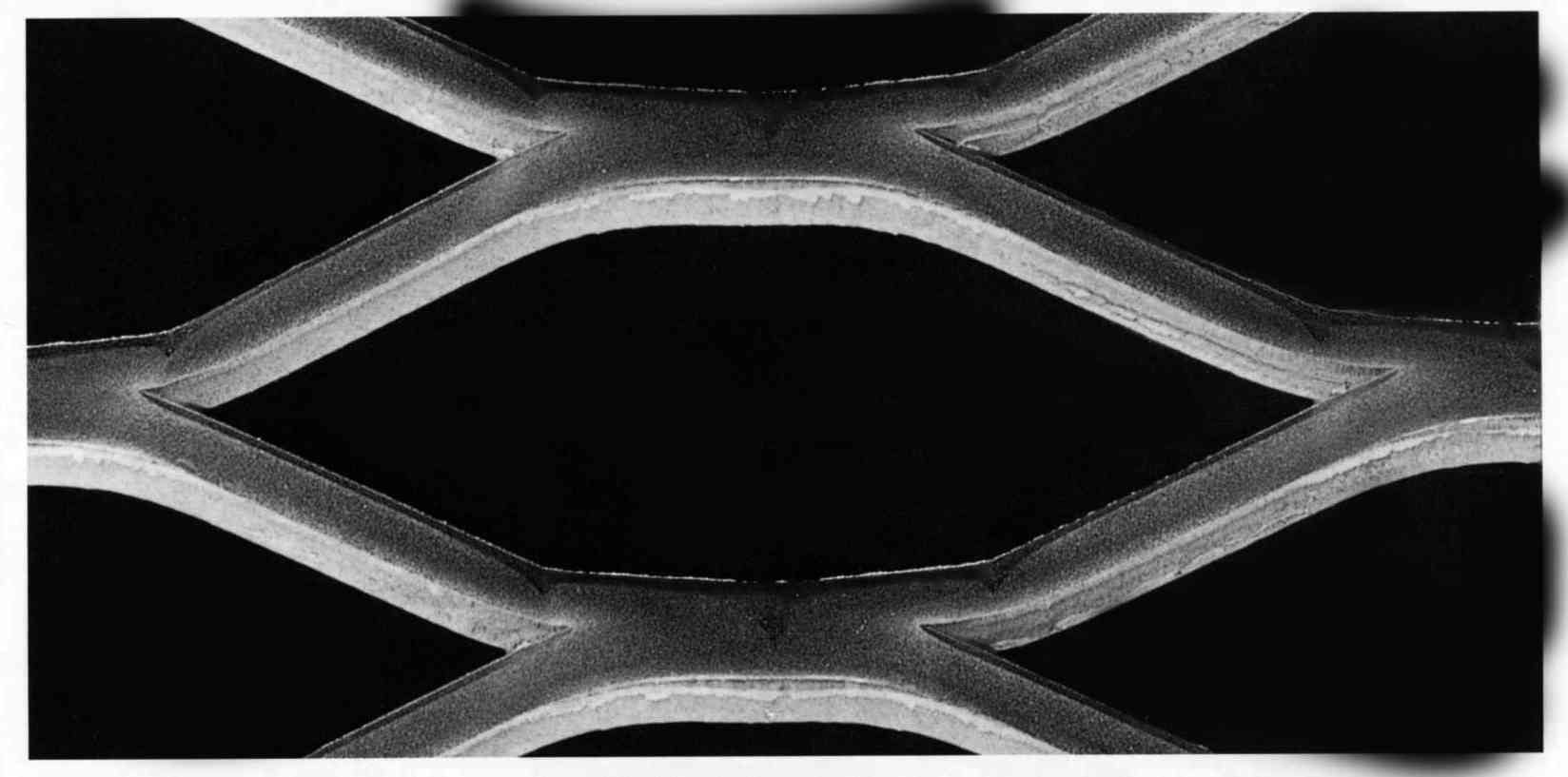

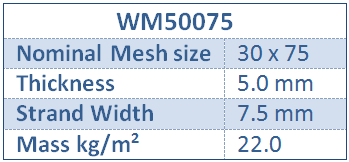

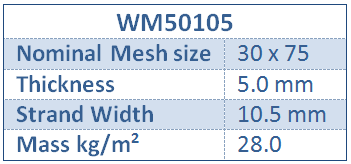

When specifying expanded metal for walkways, industrial or architectural applications, its important to understand how the different aspects of the profile are identified. Expanded metal is identified using a number of specialised terms. www.locker.com.au/industrial-flooring/gridwalk-industrial-flooringProduct codes utilise a combination of sheet thickness and strand width to identify the profile.

A feature is the provision of an excellent anti-slip surface. This makes the product suitable for ramps (e.g. inclined walkways adjacent to conveyors) platforms and stair treads.

The open nature of the product provides good visibility through the mesh as well as the easy passage of air and sound whilst ensuring security and protection.

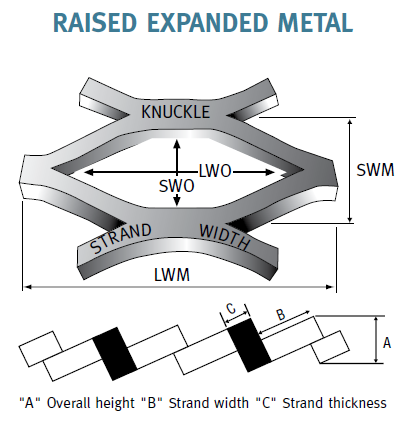

Expanded Metal Definitions

Long Way Mesh (LWM)

The distance from a point on the knuckle to a corresponding point on the following knuckle, measured across the Long Way. This distance is also sometimes referred to as the pitch.

Short Way Mesh (SWM)

The distance from a point on the knuckle to a corresponding point on the following knuckle, measured across the Short Way.

Long Way Opening (LWO)

Long Way of Opening, the distance measured from the inside of the knuckle across to the inside of the knuckle.

Short Way Opening (SWO)

Short Way of Opening, the distance measured from inside of the knuckle across to the inside of the knuckle.

Knuckle

The intersection of two strands; it is always equivalent to the width of two strands.

Overall Thickness

The actual measurement of the thickness of the mesh measured at the knuckle. (Dimension A)

WK4514 Profile WK4519 Profile

WK3022 Profile WK3028 Profile

WK2517 Profile